Granite sand making machine performance advantages

Granite is an igneous rock formed by the condensation of magma below the surface. The main components are feldspar and quartz. It is not easily weathered, has high hardness and is resistant to wear, so granite sand making machine can be used in the process of making it into sand.

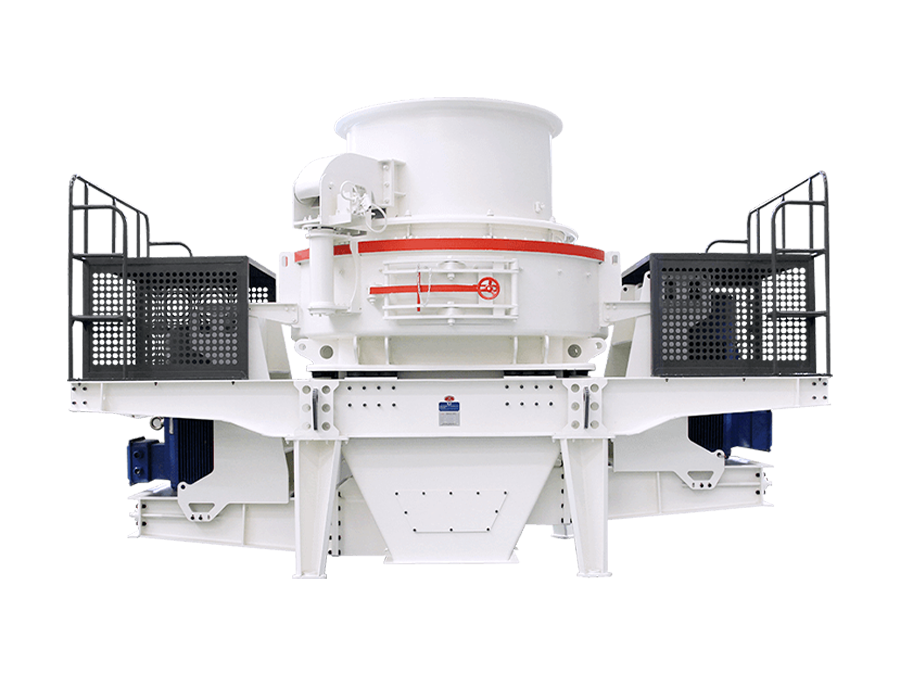

Granite sand making machine is an effective Granite Crusher with domestic and high level developed by our company with the principle and technology of “stone-on-stone” crusher introduced from abroad, combined with the actual situation of domestic sand making production.

Granite sand making machine performance advantages

The structure design is simple and reasonable:

The Granite Crusher is made by the principle of “stone hitting stone”, the structure is simple and reasonable. And free-style crushing.Special bearing installation and reasonable main shaft design make the equipment have the characteristics of heavy load and high-speed rotation , and the use cost is ultra-low; strict and reliable safety protection device to ensure equipment and personal safety

Strong adaptability to materials and good crushing effect:

The granite sand making machine can perform medium and fine crushing of materials. And also has the function of coarse grinding. It has less requirements for materials and can also be crushed when the moisture content of materials reaches 8%; the equipment Smooth operation, low noise, high efficiency and energy saving, high crushing efficiency.

Environmentally friendly and durable, with little pollution:

the internal self-circulation system of the eddy current chamber of the granite sand making machine can reduce dust pollution; all the easy-to-wear parts of the equipment are made of strong wear-resistant materials at home and abroad, and some of the easy-to-wear parts are made of extra-hard wear-resistant materials Made of material, small size, light weight, easy to replace accessories, long service life; material self-lining in the crushing cavity can greatly reduce maintenance costs, the body is free from wear and durable.

Various installation methods and high product quality:

The Granite Crusher has various installation methods and can be installed in a mobile way. Which is conducive to the crushing of materials that are difficult to transport; the Granite Crusher can be used as a stone shaping machine. , less iron pollution.

The equipment is suitable for fine crushing of various medium and high hardness solid materials. And can be used for fine crushing of granite, limestone, basalt, river pebbles, cement clinker, quartz stone, iron ore, bauxite and other materials.