Sand and gravel production line – configuration

The configuration of the sand and gravel production line is very simple and easy to understand. Crushing is the main force, screening and coordination, plus some conveying auxiliary machines, can basically build a complete sand and gravel production line. What aspects of production are included in the specific configuration? And how should the very important EIA question be passed? This article will introduce you one by one.

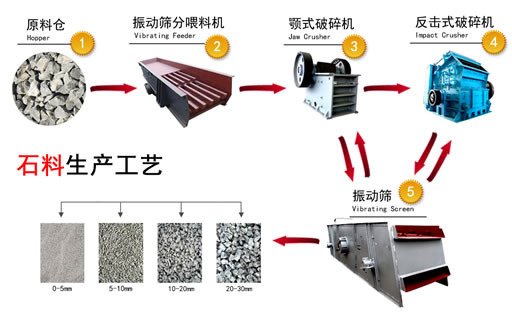

The system equipment for crushing sand and gravel aggregate generally includes crushing equipment, screening equipment, auxiliary machines, etc.

Crushing equipment includes first crushing, secondary crushing, fine crushing and other equipment (this should be equipped on demand according to the characteristics of the material).

Head crusher, generally refers to jaw crusher, is mainly used to crush large pieces of material in order to enter the next process.

Secondary crusher, generally refers to impact crusher, cone crusher, etc., here is the coarse crushed material from the jaw crusher, which is further crushed into small stones (according to the characteristics of different materials and the different needs for the particle size of the finished product) , the finished product from this step can be omitted if it can meet the needs of the next step.

Fine crushing means that the materials crushed for the second time still cannot meet the final demand (such as the demand for sand) and need to be further crushed. The machines used in this step are generally impact crushers, sand making machines, etc.

Screening equipment refers to the equipment connected after each crushing equipment to classify the discharged materials by size, and the discharged materials of different sizes are screened out and transported to different places by the belt conveyor.

Auxiliary equipment generally refers to belt conveyor, feeder, iron remover, dust collector, sand washing machine, etc.

If we want to expand the environmental protection sand and gravel production line. We can upgrade the production line from open air to indoor production line; choose environmentally friendly stone processing equipment; add dust and noise reduction configurations such as dust collectors.

If you don’t know how to plan the production line, our company can provide you with free planning and production plan services. According to your needs description, one-to-one design plan, in-depth optimization of each configuration detail. As much as possible to meet operational needs and meet your expectations standard.

The cost of upgrading the environmental protection of the sand and gravel production line is not high. Compared with the profit of the sand and gravel material you earn after the smooth start of construction. This small cost is not much. In the face of the current severe environmental protection situation, who can start production smoothly? We can take the lead in occupying the market and usher in the peak of efficiency.