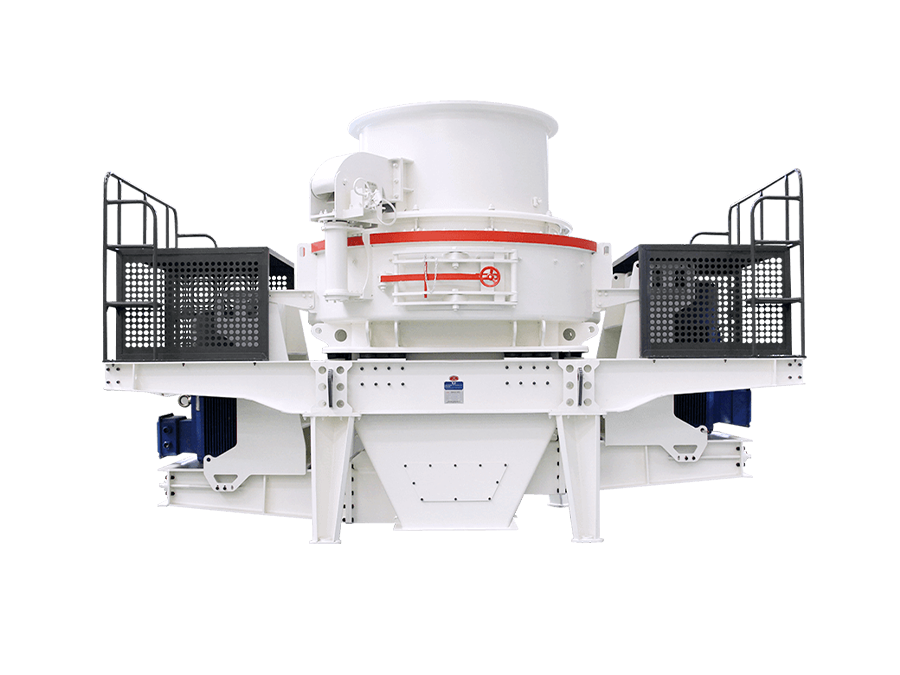

How many points are there for sand making equipment cleaning?

In the production process of the sand making machine, it is necessary to clean the equipment to prolong the service time of the equipment and parts. Then, the following editor will introduce the main points about the cleaning of sand making machine equipment.

How many points are there for sand making equipment cleaning?

- When cleaning the sand making machine equipment, the operator needs to choose the correct cleaning solution. For example, the cleaning fluid of the bearing should choose diesel or kerosene without water, but should choose the same hydraulic oil as the lubrication system, and the cleaning fluid should not use diesel oil. And when using the cleaning solution, it is necessary to ensure the cleanliness of the cleaning solution.

- When cleaning the bearing, simple cleaning work is required, and the bearing surface is cleaned with cleaning fluid. However, this method cannot remove the stickiness of the bearing, so it is necessary to carry out a delicate cleaning work on the bearing.

- The cleaning of the bearing of the sand making machine is mainly to put the bearing into a container with diesel oil or cleaning fluid, rotate it slowly, carefully check to see if there is any sticky object on the surface of the bearing, and gently scrub it with cotton yarn or a brush.

- After the parts of the sand making machine are cleaned, they need to be processed. The bearing surfaces are coated with anti-rust grease and dried. At the same time, the lubrication system needs to be replaced with a new lubricating oil.

- The cleaning of sand making machine equipment parts, such as small parts such as bolts and nuts. It is generally cleaned uniformly by the vibration method. Put it into the cleaning basket or rack of the vibrating machine, immerse it in the cleaning solution. And remove the oil from the parts by manual flushing and action of the cleaning solution.

- When cleaning the lubrication system of the sand making machine. It is necessary to turn the liquid flow in the pipeline into a flocculation state. And to complete the action of each actuator. So as to flush out the pollutants in the hydraulic cylinder and other components.

After reading the above content, if you have any other questions about sand making equipment cleaning, please contact us, we look forward to working with you.