Sand making machine fuel saving tips

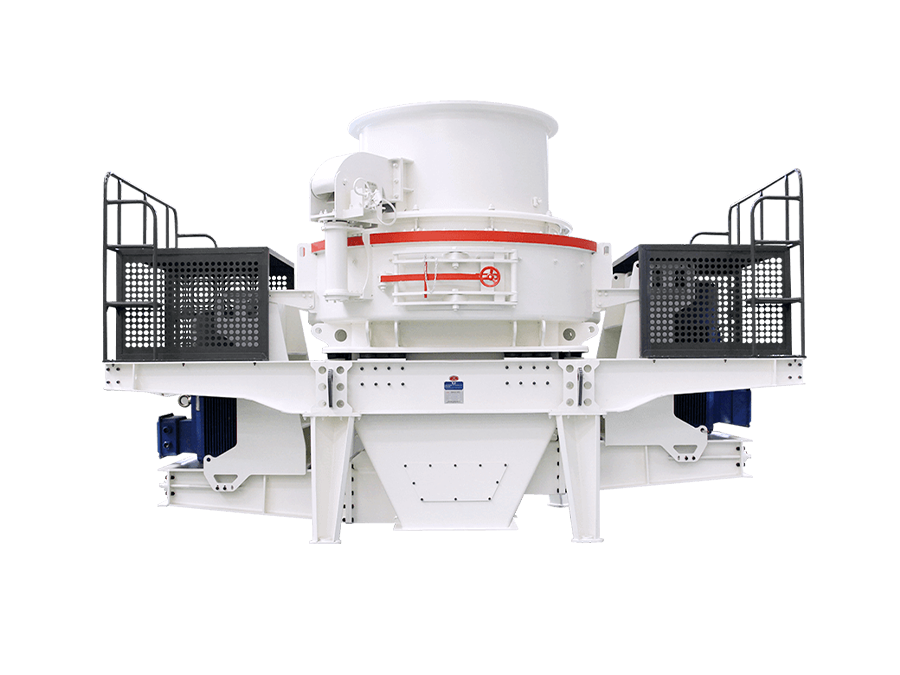

Sand making machine equipment is a machine that crushes sandstone raw materials into sand. Its working mode is based on the principle of hitting a stone with a stone. Through repeated impacts, the sandstone becomes fine sand, following the principle of crushing iron with stones.

Sand making machine equipment is a kind of production equipment, because of its small wear, high crushing rate, energy saving, little influence by the moisture content of the material, the moisture content can reach about 8%, the working noise is lower than 75 decibels, the dust pollution is less, and the maintenance is convenient, etc. Advantages, it has replaced traditional equipment such as hammer crushers, rod mills, and roller crushers, and has become the mainstream equipment in the sand making industry.

When buying a sand making machine, you must first understand the characteristics of sand and gravel. Consider your own needs, and then consider its scope of application, equipment quality and maintenance convenience.

How to maintain a better state during operation and make it more fuel efficient? Next, I will briefly introduce it.

First, check whether the sand making equipment leaks oil and whether the quality of the lubricating oil used by itself is qualified. Good oil can also save fuel.

Second, avoid idling. Oil is also consumed when the engine is idling.

Third, maintain the correct switch speed, do not switch the machine frequently. The fewer switches, the more fuel-efficient.

Fourth, be careful not to overload the sand making equipment to develop the good habit of repairing and checking in time. Solve the problem in time, and do not let the equipment continue to work under symptoms.

Therefore, skillful actions when operating the sand making equipment and operating according to the rules will keep the machine in a better state during operation. It can also save fuel for the sand making machine.