Sand making machine – why heat preservation?

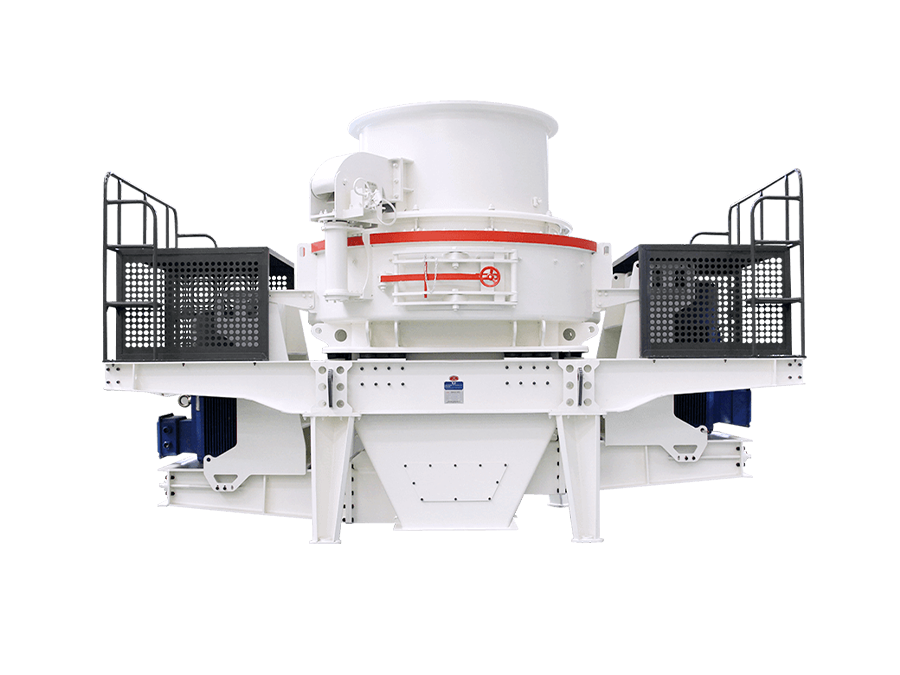

With the acceleration of domestic construction and the stricter environmental protection management and control. The sand making machine is used for the crushing of hard and very hard minerals in the sand making machine. At present, my country’s river sand collection control and market demand for sand have been strengthened. The gap is getting bigger and bigger, and sales are increasing year by year.Now that winter is coming, in order to ensure its stability. Keeping the equipment warm is a job that needs to be done.

The editor will introduce to you why the sand making equipment wants to be insulated?

Before the sand making equipment runs every day, the equipment must be preheated. When the temperature is too low. The oil in the variable temperature box should be replaced with low-temperature anti-freezing lubricating oil in time to avoid freezing damage due to too low temperature.

For the oil level V-belt of the reducer is loose. The gear wear level ensures the normal operation of the machine. And the accessories and lubricating oil should be replaced in time. If the sand making machine needs to be covered in time. The dirt on the sand making machine equipment should be cleaned regularly. So as not to affect the service life of the equipment.

Most mining equipment, such as sand making machines, are made of steel. Long-term operation in the open air or in steam is sufficient. Coupled with a period of inactivity, rust is a normal chemical reaction. The corresponding internal crushing chamber of this equipment is also corroded.

This is because the inner wall and material (usually higher hardness rocks, ores, etc.) are rubbed during the crushing process. And the inner wall is scratched and rusted. It is not important whether it is rusted or not. But it should be dealt with in time to prevent long-term rusting. Causing equipment damage and affecting the normal use of the new sand making machine.