What should be paid attention to when operating a jaw crusher?

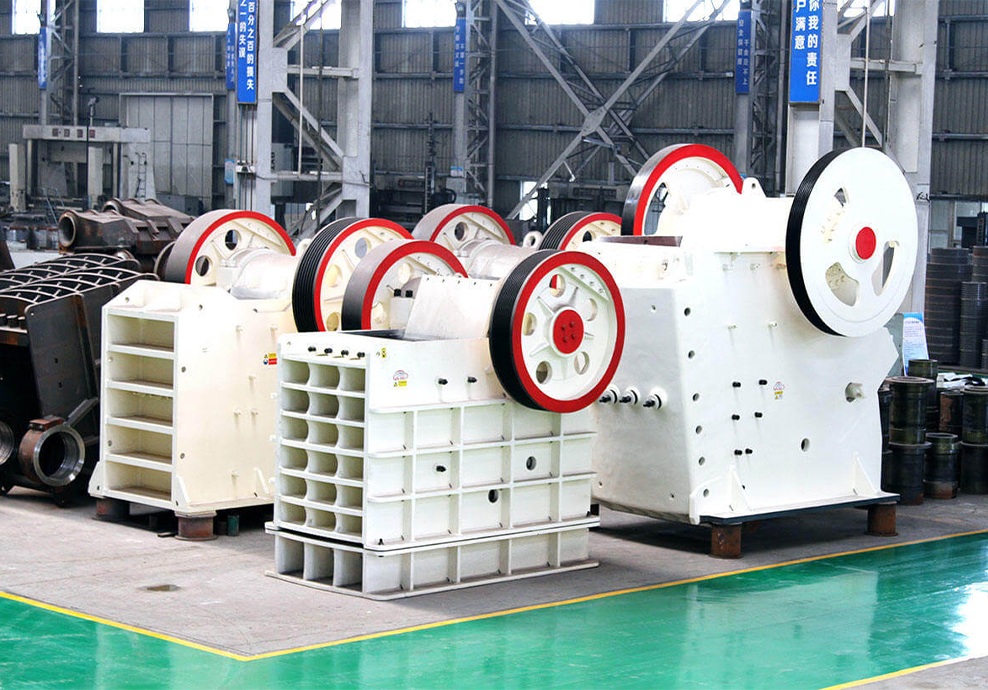

The continuous rotation of the power source motor does periodic crushing and discharging work to achieve mass production. It is a crushing equipment for various ores and bulk materials in mining and smelting, building materials, highways, railways, water conservancy, chemical industry and other industries.

1. Safety protection, install a debris shield at the operating position of the personnel to prevent the sudden flying of debris during the operation stage of the jaw crusher and cause damage to the construction personnel or the equipment itself; the operator must wear earplugs and masks.

2. The personnel should be standardized, and the jaw crusher should be operated at the specified position. In the case of drunkenness or a reaction to taking medicine, the crushing work is prohibited.

3. The operation is standardized. If a person enters the dangerous area of the operation, stop the operation immediately; for the overall operation, when the operation starts, the personnel are easily hit by the flying fragments. During the operation of the jaw crusher, strictly follow the safety operation regulations. It can be used after confirming that the installation is completed and debugging is normal.

4. The equipment is standardized and can only be used when the jaw crusher is in normal state. When disengaging the curved back for maintenance and overhaul, to ensure stable working conditions, it is necessary to lower the working device.

Correct operation of jaw crusher can not only effectively prevent losses caused by wrong operation, but also improve work efficiency and prolong service life.